Virtual Factory Tour

Virtual Factory Tour

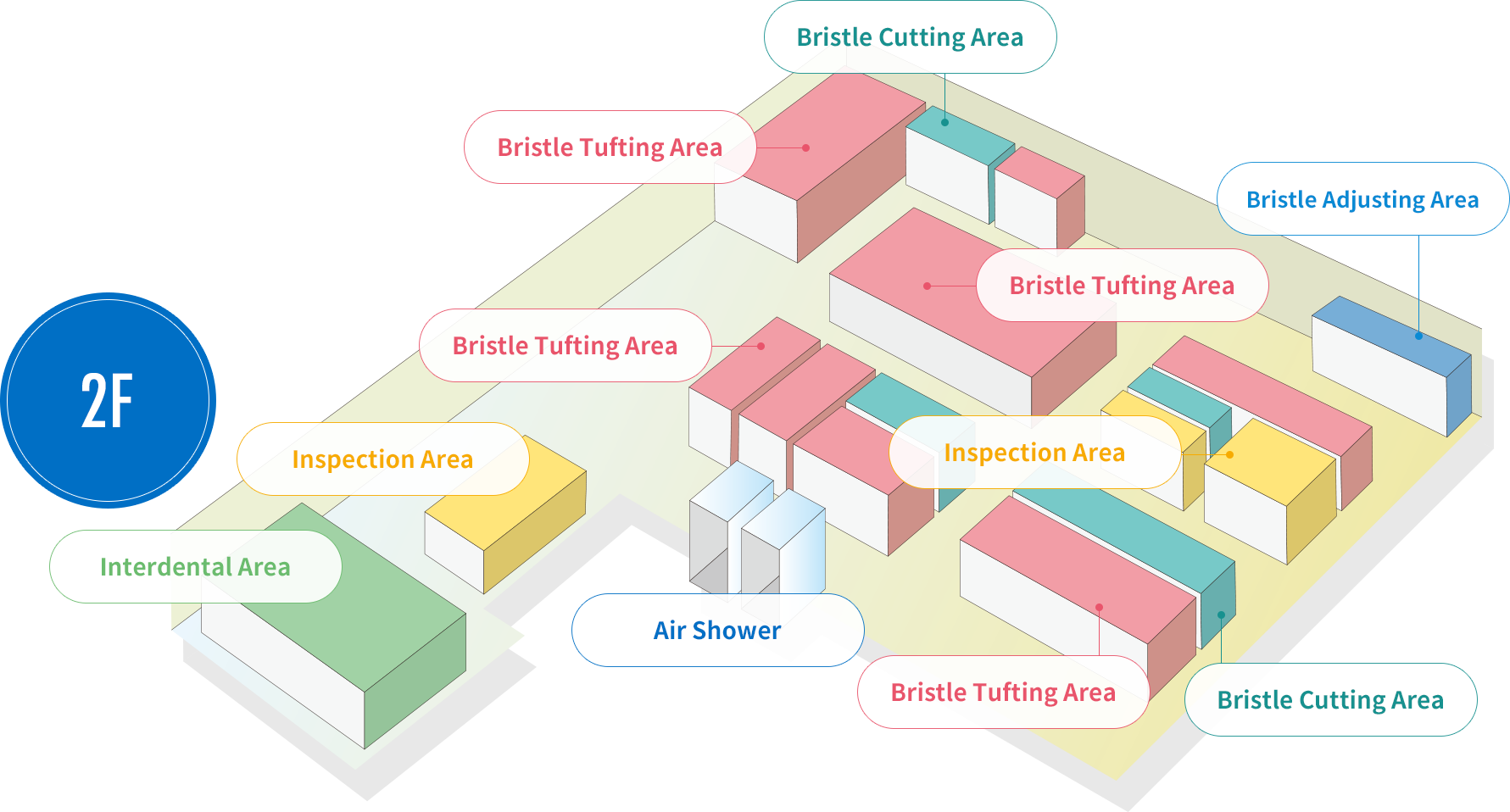

2F

Bristle Adjusting Area

This is the area for “cutting and inspection” of toothbrush bristles procured from manufacturers.

The nylon bristles arrive with an overall length of “approximately 1,200 mm,” so they are cut to “approximately 30 mm” to meet toothbrush standards.

Checks are made in the inspection following this, such as “Are the bristles in accordance with the established standards?” and “Are there any issues with the exterior appearance?”

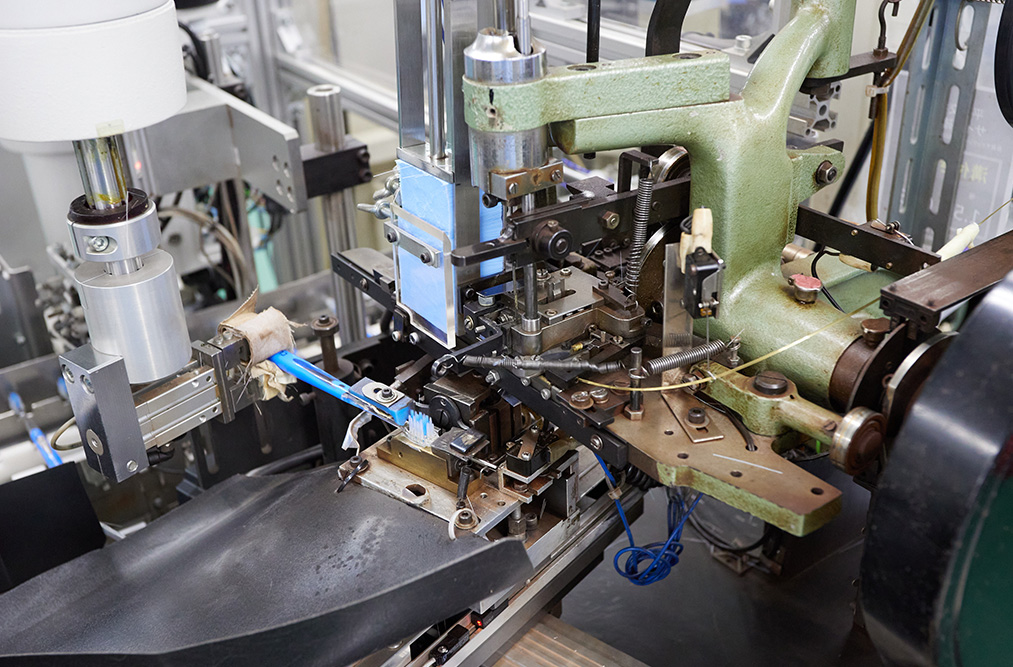

Bristle Tufting Area Tsujimura-style Tufting Machines

These are Japanese-produced tufting machines.

When compared with overseas-produced tufting machines, they are slower at inserting bristles, but it is possible for one operator to simultaneously operate multiple pieces of equipment. Therefore, it could be said that they are tufting machines “for small lots of various products.”

The characteristics of the equipment also make it suitable for the production of special brushes aside from toothbrushes.

Bristle Tufting Area Overseas-produced Tufting Machines

We use tufting machines produced in Belgium and Germany.

When compared with their Japanese-produced counterparts, they are quicker at inserting bristles and have high production capabilities.

It could be said that they are tufting machines “for big lots.”

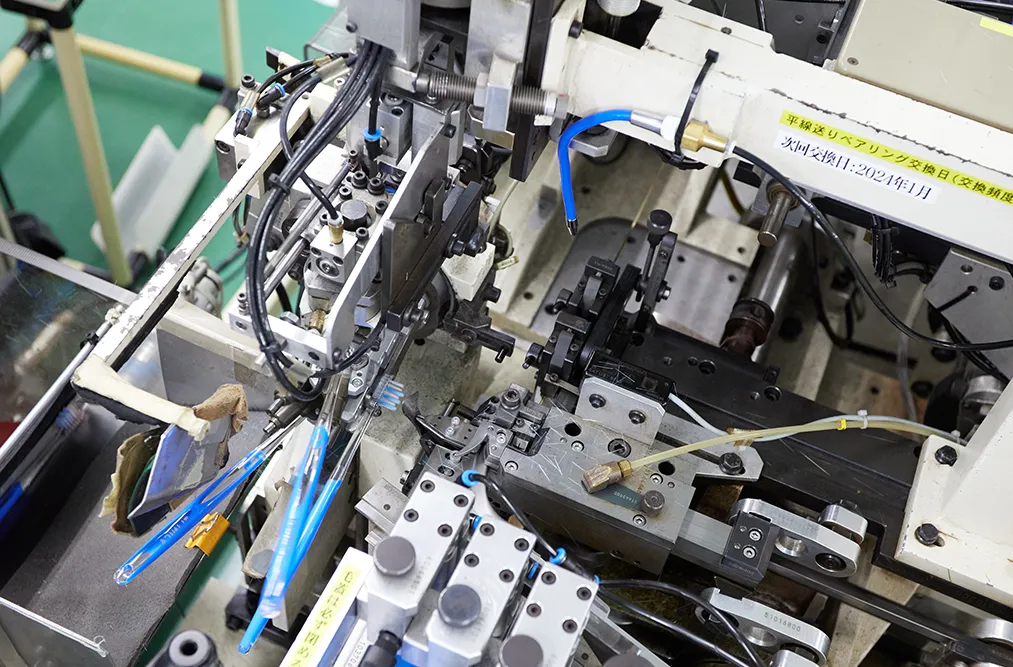

Bristle Tufting Area Overseas-produced Tufting Machines and Cutter Clutches

These are the same overseas-produced equipment as mentioned above, but they are “tufting and cutter clutches” that can perform “tufting” and “cutting” at once.

Conventionally, it is necessary to have “one person operating a tufting machine and one person operating a cutting machine,” but production is possible with “one person operating a tufting machine and a cutter clutch.”

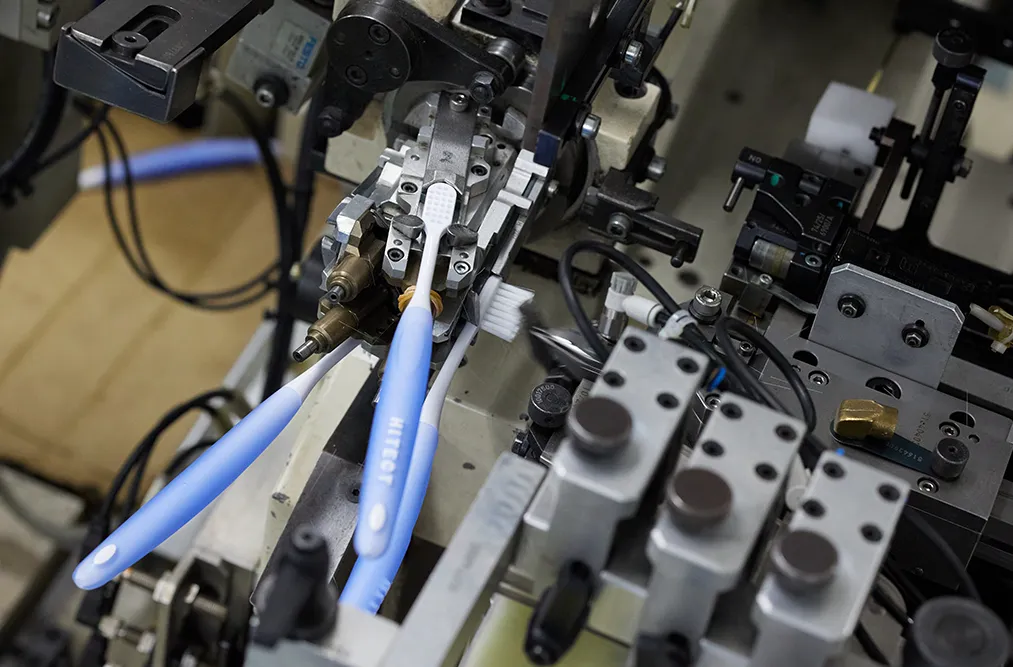

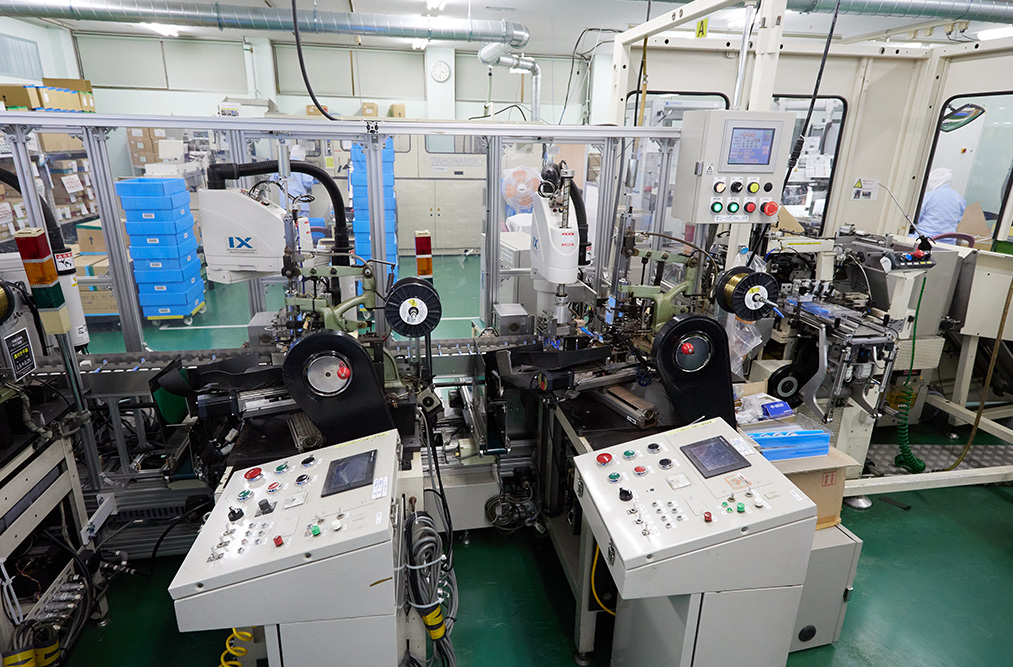

Bristle Tufting Area Tsujimura-style and Overseas-produced Tufting Machines and Cutter Clutch Line

This is our original production line that connects “Tsujimura-style tufting machines” and “overseas-produced tufting machines” via a robot.

Its forte is that it can tuft three types of bristles.

First, it tufts two types of bristles with the overseas-produced tufting machine, and then it tufts one type of bristle with the Tsujimura-style tufting machine.

It is automatically transported to the cutting machine after tufting, and cutting is carried out.

Bristle Cutting Area

This is the area for cutting bristle ends.

This is an important process that provides functionality to toothbrushes for characteristics such as “flat cuts,” “mountain cuts,” and “vertical and horizonal mountain cuts.”

Toothbrushes that have finished the tufting process are inserted into the equipment, and cutting and rounding are carried out on the bristle ends.

In the past, we have also sold cutting machine equipment to other companies in the same area of business.

Inspection Area

Here at TAIYO BRUSH, we carry out exhaustive visual inspections.

We carry out inspections of more than 50 defective items for defects that stem not only from us but also from material manufacturers.

For this reason, we have a structure where inspectors receive education and tests, and only those who pass are able to perform inspections.

Interdental Area

We manufacture brush parts for wire-type interdental brushes.

*Handle parts are produced at a molding manufacturer.

Various brush sizes are supported.

Exhaustive visual inspections are performed after completion, and they are shipped to a molding manufacturer.

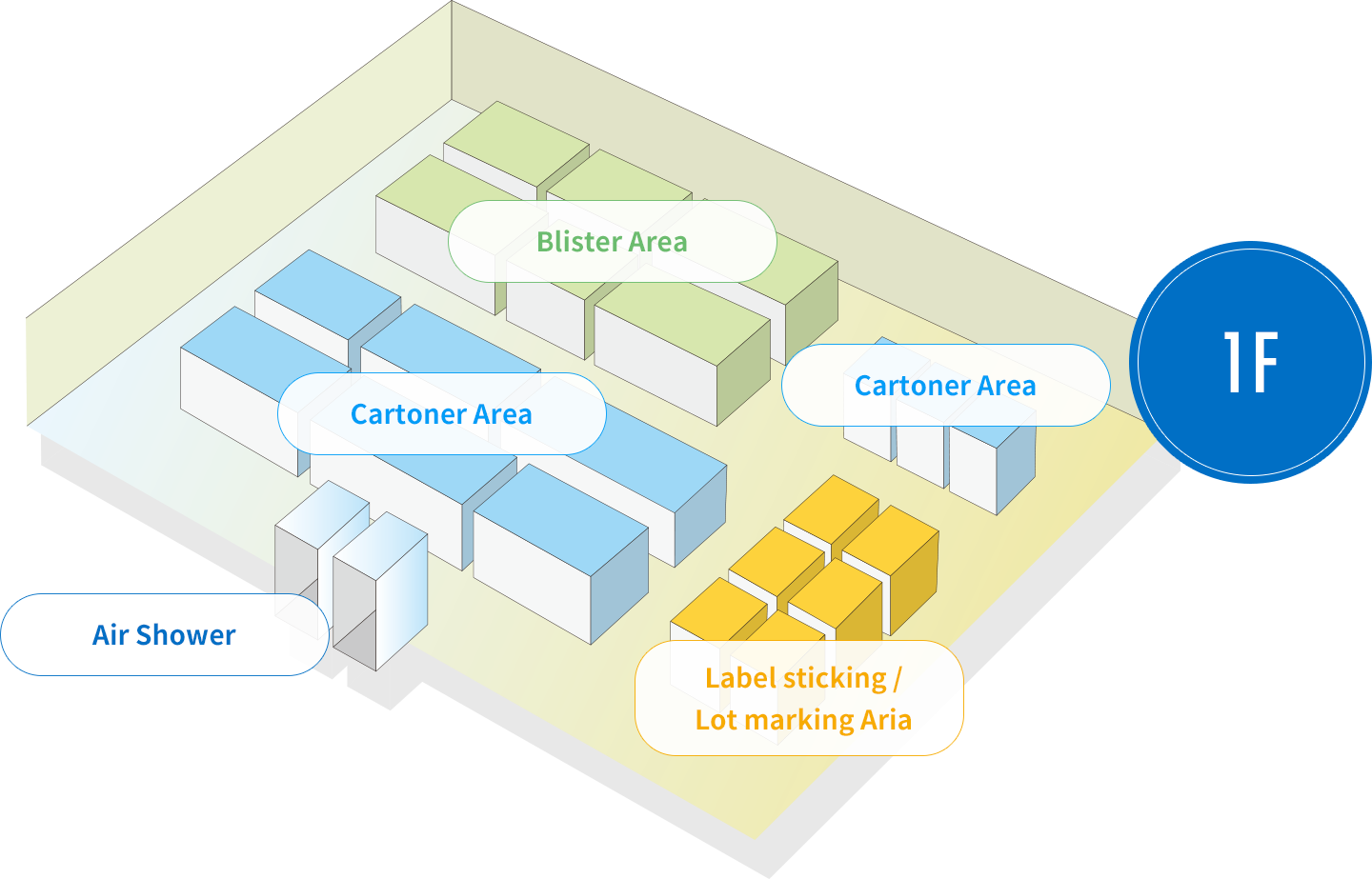

1F

Air Shower

It is necessary to pass through an air shower when entering the factory.

Rules, processes, and the like are prescribed in detail in the air shower, which we consider extremely important in order to avoid foreign substances being brought into the factory.

After passing through the air shower, an “adhesive carpet cleaner” removes such things as fiber scraps attached to clothes from tip to toe.

Cartoner Area

This is the area for packaging toothbrushes that are sold at dental clinics.

Toothbrushes are sold in individual boxes at dental clinics. By supplying the individual boxes procured from the packaging material manufacturer to equipment, it automatically assembles individual boxes. When placing each toothbrush by hand into the assembled boxes, the lids close automatically, and the process is complete.

Blister Area

This is the area for packaging toothbrushes that are sold at supermarkets, drugstores, and so on. We often happen to see toothbrushes that are blister packed at places like supermarkets. After supplying materials (blister domes and backing paper) procured from the packaging material manufacturer and toothbrushes to the equipment, the toothbrushes are loaded automatically into the blister dome pockets, and the backing paper is set to this and finished with a heat seal.