Toothbrush Production Flow

Toothbrush Production Flow

Manufacturing Process

-

flow 1Inspection of materials received

-

flow 2Adjust bristles

-

flow 3Bristle tufting process

-

flow 4Bristle cutting process

-

flow 5Inspection process

-

flow 6Packaging process

-

flow 7Shipping process

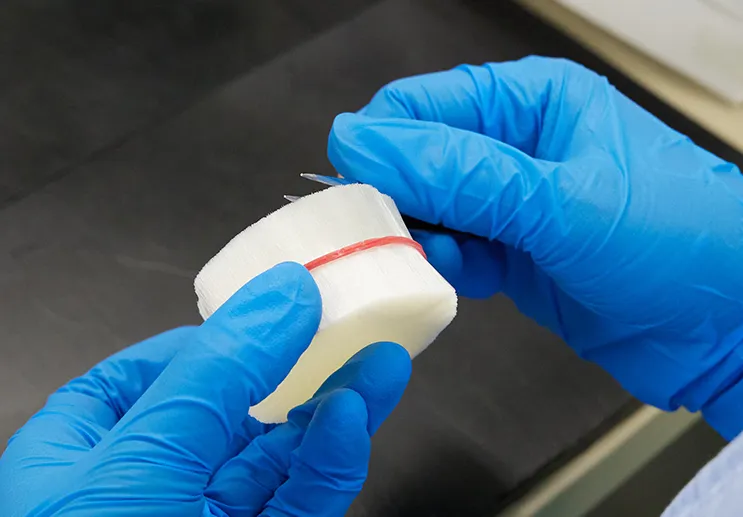

Inspection of materials received

TAIYO BRUSH often relies on the procurement of materials like "handles," "bristles," "flat lines,"

and "packaging." We carry out visual inspections of materials received from each material

manufacturer in accordance with AQL.

"Good craftsmanship starts with good materials." Our Quality

Guarantee Department is responsible for inspections

Adjust bristles

The "bristles" procured from material manufacturers are inspected, and we carry out "bristle length measurements" and "cuts" as necessary. We also carry out a process on the bristles to make them easier to handle in the next processing stage of tufting.

- Rounded bristles

- These arrive as an "overall length of approximately 1,200 mm by 50 mm in diameter." They are cut to approximately 30 mm to meet toothbrush standards.

- Tapered bristles

- These arrive as an "overall length of approximately 30 mm by 50 mm in diameter." The overall lengths are measured and separated into "long, medium, and short" pieces.

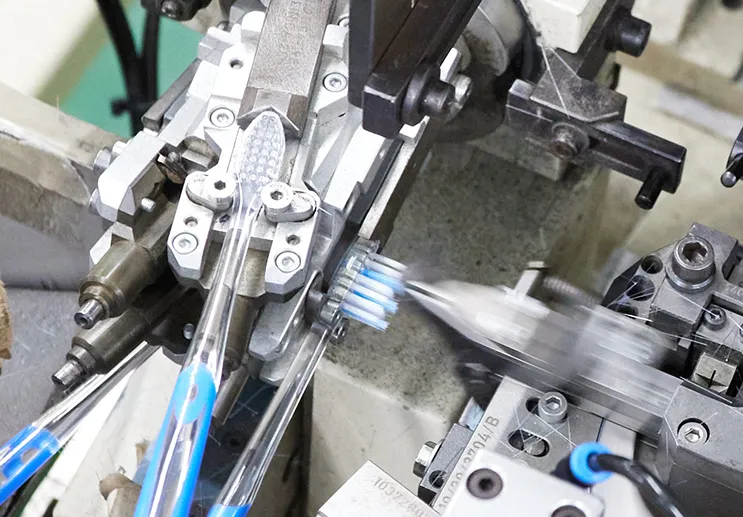

Bristle tufting process

This is the process of inserting "bristles" into the "handle." Brass, called a "flat line," is used to insert the bristles into the holes one by one. Technology is required to "stabilize the number of bristles for each hole" and to "arrange the bristle ends and insert the bristles."

The speed of bristle tufting is "1,000 holes (or 50 toothbrushes) per minute!"

*Depends on

specifications.

Bristle cutting process

Processing is carried out to meet the characteristics of each product, such as "flat cut" or "mountain cut," and the bristle ends are rounded so that they don't damage gums. The bristle rounding process involves sliding the ends of the cut-off bristles over a file in various directions to remove the corners.

The precision of cuts is operated at ±0.2mm!

*Depending on specifications

Addition: We sharpen the “cutting instruments” on site that are core to the bristle end process!

Inspection process

We carry out exhaustive visual inspections.

We carry out inspections not only of defective items

stemming from us but also of material manufacturers.

We inspect over 50 defective items!

Employees authorized with the necessary skills conduct

inspections!

Packaging process

We support various packaging specifications, such as "blister packs" and "individual

containers."

We package each toothbrush that has been inspected and place them into internal or

external containers.

We take great care during operations to avoid mixing foreign substances,

etc.

We are trying to reduce costs by advancing with automation!

Shipping process

We conduct inspections prior to shipping to check that our products have been manufactured in

accordance with standards.

We take great care to ensure that nothing happens during transport,

such as load collapse, and that we ship our products safely.

To meet customer needs, you can choose between charter or scheduled flights.